In the context of mandatory product labeling under the ASL BELGISI system, it is essential for businesses in Uzbekistan to quickly and accurately apply Data Matrix codes to product packaging. For this, specialized devices are required — reliable MERTECH label printers that fully meet the ASL BELGISI requirements.

A label printer allows you to independently print stickers with codes and product information without contacting a print shop. This significantly speeds up the labeling process, simplifies logistics, reduces costs, and makes the business more flexible.

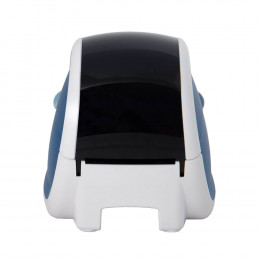

MERTECH is a manufacturer of modern weighing and printing equipment with supply coverage across the CIS. For entrepreneurs in Uzbekistan, we offer officially certified printers, local service, and support in both Uzbek and Russian.

Key facts about ASL BELGISI requirements

Starting from 2025, the ASL BELGISI digital labeling system will become mandatory for more and more product categories in Uzbekistan. Each unit of goods must be labeled with a unique code — most often a two-dimensional Data Matrix code.

This code contains information about the manufacturer, production date, batch, and other product data. It is essential for tracking the product’s path from production to the final customer. The system helps combat counterfeits and simplifies tax administration.

To print labeling codes, it's important to use compatible printers that can accurately apply the required information in a format that meets ASL BELGISI technical specifications. In most cases, printing on self-adhesive labels is required — this is where thermal and thermal transfer printers are used.

How Thermal Printers Work: Fast, Simple, but Not Forever

Thermal printers are direct thermal printing devices that do not use ink or ribbons. Instead, they create images using a heated thermal printhead that contacts special thermal paper. Under the influence of heat, the paper darkens in the desired areas, forming barcodes, text, or logos.

The main advantage of a thermal printer is simplicity and low operating cost. There's no need to purchase ink or ribbons, and the printers are usually compact and easy to use. That’s why these devices are often chosen by small shops, pharmacies, bakeries, and kiosks.

However, there are also disadvantages: labels printed this way tend to fade over time, especially when exposed to sunlight, heat, or moisture. The life span of a label varies from a few months to a year depending on storage conditions.

Therefore, thermal printers are best suited for short-term labeling tasks: food products, receipts, or in-warehouse logistics stickers.

Thermal Transfer Printer: Durable Printing for Serious Tasks

Unlike thermal printers, thermal transfer printers use an additional consumable — a ribbon. This is a special ink-coated film that transfers the image onto the label under high temperature. This method ensures durable and high-contrast printing that resists moisture, abrasion, and sunlight.

Thermal transfer printing is ideal for labeling clothing, cosmetics, household chemicals, electronics, and products with long shelf life. These printers are favored by exporters, logistics centers, warehouses, factories, and pharmacies.

Yes, thermal transfer printers require more expensive consumables: in addition to labels, you need to purchase ribbons. However, these costs are justified by the quality and durability of the print. A label with a Data Matrix code printed by a thermal transfer printer remains readable for up to 5 years.

All MERTECH printer models support thermal transfer printing. Thanks to the high-quality Japanese ROHM printheads and reliable mechanics, these devices can handle thousands of labels daily.